wdc

Newb

Posts: 37

|

Post by wdc on May 11, 2019 12:49:41 GMT -8

Sorry all, forgot to add this, just to show my jig and how I went about it.

Good luck on yours!

WDC

|

|

|

|

Post by barnaby on Jun 28, 2019 8:40:32 GMT -8

I have a chrono wheel with a loose 4th wheel so I'm going to attempt this repair. I'm a bit apprehensive- I hate using glue, and I'm relatively new to horology.

A couple of questions:

what is the name of the tool you're using to hold the chrono wheel?

do you use 5min epoxy because it takes too long for the longer setting stuff to reach a workable consistency?

|

|

|

|

Post by barnaby on Jun 28, 2019 12:05:49 GMT -8

Re-reading your guide, I'm still not 100% clear about everything (mainly exactly where you are applying the epoxy). Perhaps you could clarify the terms "spur-gear" and "hub"?

Corrrect me if I'm wrong with my understanding so far: the spur gear looks like a 3-level wedding cake. The lowest part is the widest part, and interfaces with the 3rd wheel. So that's the 4th wheel pinion right? Then the middle level, which is a bit narrower, and then the top level, which is narrowest. The 4th wheel needs to be fixed so that it is right above the the pinion, and the middle level and top level of the spur-gear are above it.

So what is the part that you are calling "the hub"?

Where are you applying epoxy in phase 1? Where are you applying epoxy in phase 2? When you say that you musn't get epoxy in the spur-gear, you mean just the bottom level (pinion) right?

A diagram might be more helpful than photos...

|

|

pip

WS Benefactor

Berkshire, UK

Posts: 6,187

|

Post by pip on Jun 28, 2019 14:37:15 GMT -8

Sorry all, forgot to add this, just to show my jig and how I went about it. Good luck on yours! WDC Superb information thank you. And I heartily approve of you music choice in the video, a great song! |

|

kue

Timekeeper

Posts: 598

|

Post by kue on Aug 17, 2019 8:43:55 GMT -8

wdc Thanks for the excellent efforts and detailed instructions. I am pleased to say that this has lead me to successfully replacing a broken chronograph finger. I wasn't sure how easily you found removing the collet, but I found it was a bit awkward and feared damaging the finger. Funny thing is, I recently asked a friend to send me any 6138 chronograph wheels he could spare. He said he will send some and there should be at least one working or one that I can probably get to work. I received a bunch of chronograph wheels that the forth wheel was loose or the finger was missing. I asked him about this and he said he has been harvesting the fingers and putting it on otherwise chronograph good wheels!?!?! One of which was in a Bullhead he sold me and the finger was loose enough to go under the intermediate minute recording wheel and also rub against the bridge and stopped moving when the chrono on. After much head scratching and many tear downs and rebuilding, I restaked the collet and it worked. I am now confident, with the spares I have, to fix at least 2-3 fully working wheels thanks to this info.

|

|

HiBeat

Global Moderator

SEIKO Iko Iko GDTRWS

Posts: 8,874

|

Post by HiBeat on Aug 17, 2019 9:06:30 GMT -8

Wow good stuff.

I have broken off a few Chrono fingers trying to tweak adjustment at which point I have always considered the part toasted.

|

|

kue

Timekeeper

Posts: 598

|

Post by kue on Aug 17, 2019 10:02:18 GMT -8

Yep, the broken finger is one I'm guilty of too. Although you might be able to shape the broken end just right to get it working again (I managed to buy a Jumbo with this repair 😡).

I always kept the broken wheels as I thought there must be a way to repair these and that someone could repair it for me.

|

|

Adrian-VTA

Global Moderator

Adelaide, South Australia

Posts: 5,327

|

Post by Adrian-VTA on Aug 18, 2019 6:17:03 GMT -8

You can re-use the chrono fingers.

As for the rest of the wheel,

I like the risk taking of pulling the assembly apart and trying to find new ideas but I'm absolutely certain glue isn't the answer. This will split again on about the 10th reset.

The better way to go would be to close the hole then press the 4th wheel on. No glue required. It will probably come off again at some point but I'd say the repair would last longer.

I have considered having a go at making a clutch spring, as I think it could be made as a replaceable part without staking the assembly apart, but it's on my "to do one day" list. It's a bit of work.

|

|

kue

Timekeeper

Posts: 598

|

Post by kue on Aug 18, 2019 23:38:19 GMT -8

You can re-use the chrono fingers. As for the rest of the wheel, I like the risk taking of pulling the assembly apart and trying to find new ideas but I'm absolutely certain glue isn't the answer. This will split again on about the 10th reset. The better way to go would be to close the hole then press the 4th wheel on. No glue required. It will probably come off again at some point but I'd say the repair would last longer. I have considered having a go at making a clutch spring, as I think it could be made as a replaceable part without staking the assembly apart, but it's on my "to do one day" list. It's a bit of work. I would admit I was a bit cavalier with my attempts, but this is what I found. The fourth wheel hole can be reset and restaked to pinion no problem. The issue is the clutch plate won't stay on the pinion. Tried to widen the pinion a bit but it split. So a new clutch plate with a smaller hole, malleable shim or soldering might work. The clutch spring is also attached to to a collet which is difficult to remove without damaging the spring. Good luck with the clutch spring. |

|

|

|

Post by Benchdweller on Aug 20, 2019 18:28:26 GMT -8

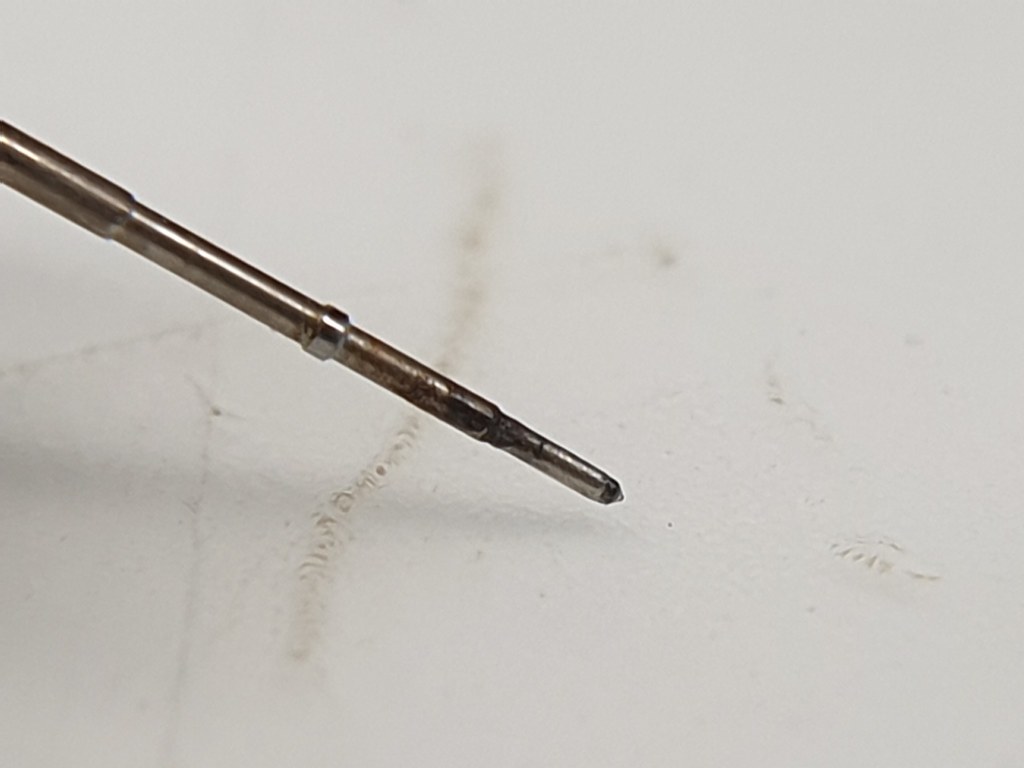

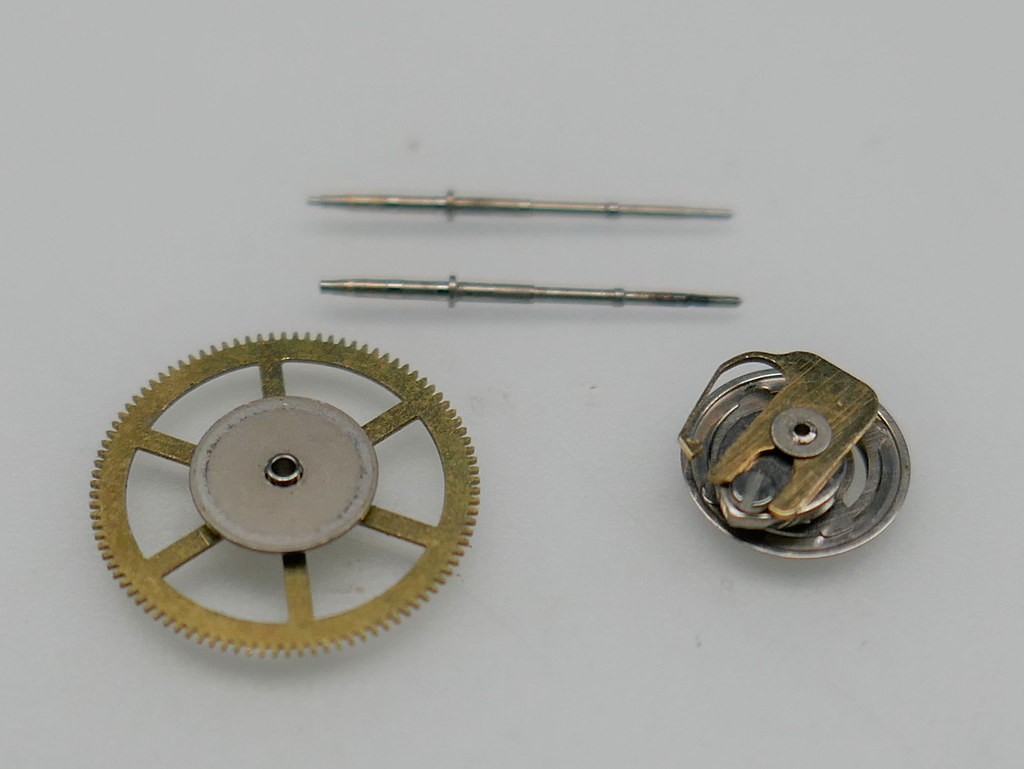

I was going to start a thread in the repair section then discovered this one already going so I might as well reply... I've had a 6138 Panda sitting here for over eight months that had a busted clutch. I know from my last search that the 6138 chrono wheels are particularly scarce but a week or two back I sourced a complete movement and crossed my fingers that the chrono wheel was good. The clutch was fine, but the tip was badly corroded and would probably snap pressing the seconds hand on or resetting the chrono, and for good measure the pivot had snapped off -   I knew I had the parts to make one good wheel and I've pulled apart other broken wheels before out of curiosity, so I scratched my head for a bit and came to the conclusion that putting the shaft in a pin vice and using two 1.2mm screwdrivers as levers and pressing on the pinion gear was possibly the only way to get it all apart without damage, if it worked of course. I tried it on the one with the busted clutch first and it did work, which left me with this -  I do the same to the good clutch/bad shaft wheel the same way and I'm left with this -  ...and using a staking tool I press it back together -  Easy! Except it wasn't. First attempt had me staking the parts too tightly and the watch would stop when the chrono was stopped. Next attempt had me staking it too loosely so the seconds hand would reset to random positions due to the heart portion slipping, so for the third attempt I used a jewelling tool to press it together so I could feel the friction of the parts pressing then coming to a stop. It's now working fine and the amplitude drops by around 20deg with the chrono stopped so it seems good and I'm not going to mess with it any further. Stopping and resetting is all good so far but I do baby all my chronos making sure the seconds hand is near zero before resetting. It's still early and my chrono wheel could explode in the next few days or weeks, so at risk of it coming back and biting me on the arse I'm going to say yes, they can be fixed. |

|

kue

Timekeeper

Posts: 598

|

Post by kue on Aug 20, 2019 23:25:28 GMT -8

I was going to start a thread in the repair section then discovered this one already going so I might as well reply... I've had a 6138 Panda sitting here for over eight months that had a busted clutch. I know from my last search that the 6138 chrono wheels are particularly scarce but a week or two back I sourced a complete movement and crossed my fingers that the chrono wheel was good. The clutch was fine, but the tip was badly corroded and would probably snap pressing the seconds hand on or resetting the chrono, and for good measure the pivot had snapped off - Thanks for sharing. I did a shaft replacement on a wheel with a broken tip and the seconds hand would fly off when reset. I was going to re-key the tip instead but wanted to try the replacement. I used hand remover levers instead of screwdrivers but for individual components and not the entire stack. I wasn't going to try another without making some tools for it, but I will give your technique a go. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Oct 13, 2020 1:27:14 GMT -8

I've repaired these using 2 broken chrono wheels to make 1 good one. In fact my 6138-8030 uses a repaired wheel. I didn't use any expensive tools either. A pair of tweezers, a pair of pin cutters and a staking set. It's all about not being a gorilla taking them apart.

|

|

gerd67

Can't Tell Time

Posts: 2

|

Post by gerd67 on Aug 25, 2023 20:09:00 GMT -8

Hello from Germany,

Its possibly everyone can share me the Video "how to dismantle the Chronograph wheel"

Regards

Gerhard

|

|

gerd67

Can't Tell Time

Posts: 2

|

Post by gerd67 on Aug 25, 2023 21:21:33 GMT -8

Hast anybody tried to make the penshaft very cold with an Coldspray Like -20 degress, maybe the disassamble is easier...

Regards

|

|

Fergus

Needs a Life!

Posts: 3,276

|

Post by Fergus on Aug 25, 2023 23:20:46 GMT -8

I very much doubt it will shrink sufficiently to release the parts.

Having recently tweaked a 6139B (888612) spring how, if it is disassembled, does one re-assemble it with parts correctly aligned. I was considering this to work the spring but decided, in no uncertain terms, that it would be a right bugger.

|

|

evildani

Timekeeper

Sadly I can only wear one watch at a time

Posts: 315

|

Post by evildani on Nov 29, 2023 18:15:40 GMT -8

Reviving this thread as I am starting to service my seikos. Mix between 6138 and 6139. First I want to see if I understand how the center wheel works.  Start/stop is done by an insertion between the two plates marked 3 in the picture. That splits them apart and applies friction against #2 stopping it, or releasing the insert, that brings the two plates close together, releasing #2 and let it move again. Right? The fix is staking or glueing 1 and 2 together so that 2 is perpendicular to the wheel axel and the distance between 2 and 3 is the correct so that start/stop works. Right? But in order to get there 3 and 4 needs to be removed from the axel. And they are friction pressed to the axel. Right? Thanks for the clarifications. |

|

Fergus

Needs a Life!

Posts: 3,276

|

Post by Fergus on Nov 29, 2023 20:05:54 GMT -8

What you are showing is the feature of centre chronograph wheel for a 6138 (888611) and 6139B (888612) Item 3 is in fact 2 parts, the clutch disc or ring and the clutch plate which as you correctly say are moved apart to stop/start the seconds hand. So when in their relaxed state, when the chronograph wheel is not activated, the 2 parts are touching. The first and second coupling levers disengages them by about 0.1mm to stop the seconds hand. Item 4 and the top part of item 3 are fixed to the centre stem, Item 1 (wheel and its pinion) and the bottom part of item 3 (clutch plate) are fixed to each other but then separated (free to rotate on the centre stem) by an internal plain bearing which must be lubricated. Yes the wheel has to be re-swagged to item 1 (pinion). Just a point to note a 6139A centre chronograph wheel (888610) does not have a clutch plate, the clutch disc acts directly onto the wheel. www.watchrepairtalk.com/topic/11414-seiko-61386139-repair-procedure-of-center-chronograph-wheel/ |

|

|

|

Post by inscription on Nov 30, 2023 1:34:15 GMT -8

I think the comment in bold is incorrect:

Start/stop is done by an insertion between the two plates marked 3 in the picture. That splits them apart and applies friction against #2 stopping it, or releasing the insert, that brings the two plates close together, releasing #2 and let it move again. Right?

Wheel number 2 drives the escape wheel so cannot be stopped.

|

|

Fergus

Needs a Life!

Posts: 3,276

|

Post by Fergus on Nov 30, 2023 2:32:42 GMT -8

To concure with inscription item 1 (pinion), item 2 (wheel) and item 3 (lower part, clutch plate) are all one sub assembly. Which brings us to the question. Which is considered the better option, to have the seconds hand running or stopped when the movement is wound and the chronograph not in use. 1. When running the plain bearing inside the wheel pinion is stationary. The aft end of the stem is running in a jewel BUT the fore end (steel) is running inside the centre wheel (steel). All parts should be lubricated. 2. When stopped the sub assembly (items 1, 2 and lower 3) run on the stationary stem via the plain bearing...which again should be lubricated. I prefer to have the chrono running. |

|

saldog

WS Benefactor

Aspiring to be a savant, but for now just a watch idiot

Posts: 1,269

|

Post by saldog on Nov 30, 2023 17:05:12 GMT -8

To concure with inscription item 1 (pinion), item 2 (wheel) and item 3 (lower part, clutch plate) are all one sub assembly. Which brings us to the question. Which is considered the better option, to have the seconds hand running or stopped when the movement is wound and the chronograph not in use. 1. When running the plain bearing inside the wheel pinion is stationary. The aft end of the stem is running in a jewel BUT the fore end (steel) is running inside the centre wheel (steel). All parts should be lubricated. 2. When stopped the sub assembly (items 1, 2 and lower 3) run on the stationary stem via the plain bearing...which again should be lubricated. I prefer to have the chrono running. I agree it's best to have the chrono running all the time. Not only because it's better to have the upper pivot running in a jeweled bearing and the middle pivot stationary (wrt the other half of the chrono pivot), it's also best to not keep the clutch spring compressed all the time. I think some of these chrono wheels have their clutches lose their spring force and then begin to slip, causing the sweeper to stop at 59 seconds as it encounters the minute counter wheel. Does that happen because the watch is stored for long periods of time with the clutch engaged? |

|