Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Oct 26, 2019 14:46:44 GMT -8

I figured it was time to put some myths to bed about the three versions of this movement. There is often talk about the 7s26A being a poor to mediocre time keeper that is not adjustable. The truth is that it can be adjusted to keep as good time as the B and C versions. After all they are the same movement. Let's look at the three balance assemblies... 7s26A  This one has a fixed and nonadjustable stud. It also has a regulator that can only be adjusted by bending the regulator pin. Knocks and jars do not generally cause the hair spring to jump around and get hooked on anything. This is because the spring is held captive by the regulator bar/pin assembly. To make adjustments at the stud end, the spring has to be bent. To make adjustments at the regulator, the pin has to be bent slightly to allow the hairspring to slide in the space between it and the bar then bent again to close the gap so that the spring does not move back and forth. Often, new enthusiasts will try to regulate the watch and end up putting a nasty kink in the spring because it is not free to slide in the regulator. This is a pain for watchmakers and also time consuming at the factory. Once these adjustments are made, the 7s26A can be just as accurate and consistent as the other two versions. 7s26B  Seiko updated the 7s26A balance system with the Swiss lie etachron stud and regulators. Both pieces have rounded rectangular heads so that they can be rotated. The stud can be rotated so that the spring shape can be modified without actually bending it. The regulator now has two pins that are parallel to one another and when the head is rotated, the pins open or close around the spring. Again no bending required. This setup cuts way down on assembly time at the factory and makes it a lot easier to get optimum performance from the movement. Unfortunately, in the 7s26B model, the design of the balance assembly is flawed. With a new spring material and longer regulator pins; the spring is somewhat floppy and easily knocked out of place and often gets looped around the outside of the stud or the regulator itself(as seen in this photo). Thus the many complaints about the B version. 7s26C  The 7s26C looks to be identical to the 7s26B but there are some real differences. Firstly, Seiko shortened up the regulator pins while redesigning the whole balance assembly. This was done to correct the previous issues and also to rationalize inventory across the 7s, 4r and 6r calibres. Balance assemblies will interchange between the A and B versions but the C version only fits in itself. All three calibres can be made to run as accurately as one another. The looping hairspring issue with the B version leaves us with the A and C as the better choices. From an adjustment point of view, the C version is probably the best overall. Hopefully, this clears up some of the misinformation floating around on the forums  Addendum: Spencer Klein has actually taken the hairspring from an A version and transplanted it into a B version with excellent results. He has also found that the B and C versions often have improper oiling right from the factory which no doubt accounts for some of the performance issues right out of the box. |

|

|

|

Post by saul on Oct 26, 2019 15:05:32 GMT -8

There is the other issue, one which Spencer often mentions, which is a problem with the 7s26c, 4r, and 6r movements. Inconsistent and imprecise lubrication at point of manufacture. I cannot validate the veracity of this as a widespread and systemic issue but it has been an issue he has observed on multiple exemplars that cross his bench. He is quick to point out that properly lubricated and regulated the entire family is capable of very good numbers and accuracy. But he is a 7s26a fan. I have had all three, one 4r, and one NH35, and have not had any issues with any of them. But given the sheer numbers of these movements produced one would hope that the out of the box performance would tend toward consistency and within spec.

|

|

HiBeat

Global Moderator

SEIKO Iko Iko GDTRWS

Posts: 8,855

|

Post by HiBeat on Oct 26, 2019 15:16:19 GMT -8

Thanks Peter that is a concise summary and lays it out for all to see with great visuals.

I alluded to a bunch of this in a recent post about the old vs new SKXs. Kinda funny because I was thinking of you when I wrote that the A had it’s aficionados. Now here you are explaining it so clearly. Thanks !

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Oct 26, 2019 16:15:53 GMT -8

Thanks Peter that is a concise summary and lays it out for all to see with great visuals. I alluded to a bunch of this in a recent post about the old vs new SKXs. Kinda funny because I was thinking of you when I wrote that the A had it’s aficionados. Now here you are explaining it so clearly. Thanks ! Jon, I debated adding to that thread but decided it needed it's own place. Adrian, rightfully, pointed out that there is a lot of misinformation about this calibre and I felt it time to express what my experience has shown. Hopefully this thread will offer some insights to those new to the 7s26 and it's brethren  |

|

|

|

Post by saul on Oct 26, 2019 16:30:24 GMT -8

Thanks Peter that is a concise summary and lays it out for all to see with great visuals. I alluded to a bunch of this in a recent post about the old vs new SKXs. Kinda funny because I was thinking of you when I wrote that the A had it’s aficionados. Now here you are explaining it so clearly. Thanks ! Jon, I debated adding to that thread but decided it needed it's own place. Adrian, rightfully, pointed out that there is a lot of misinformation about this calibre and I felt it time to express what my experience has shown. Hopefully this thread will offer some insights to those new to the 7s26 and it's brethren  I have a lot of affection for 7s26 based watches and I do not find the lack of hand wind or hacking to in any way be a detriment. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Oct 26, 2019 16:41:22 GMT -8

There is the other issue, one which Spencer often mentions, which is a problem with the 7s26c, 4r, and 6r movements. Inconsistent and imprecise lubrication at point of manufacture. I cannot validate the veracity of this as a widespread and systemic issue but it has been an issue he has observed on multiple exemplars that cross his bench. He is quick to point out that properly lubricated and regulated the entire family is capable of very good numbers and accuracy. But he is a 7s26a fan. I have had all three, one 4r, and one NH35, and have not had any issues with any of them. But given the sheer numbers of these movements produced one would hope that the out of the box performance would tend toward consistency and within spec. Good to note Saul  Spencer also found issues with the escape system on the 'B' and perhaps the 'C' as well. In one example of a 'B' that he could not make behave, he replaced some 'A' parts into a 'B' and got the results expected. The movement then performed as it should have. I don't know if Seiko changed the escapement on the 'C' version but it stands to reason that they should have; knowing the short comings of the 'B'  |

|

Adrian-VTA

Global Moderator

Adelaide, South Australia

Posts: 5,327

|

Post by Adrian-VTA on Oct 29, 2019 21:05:59 GMT -8

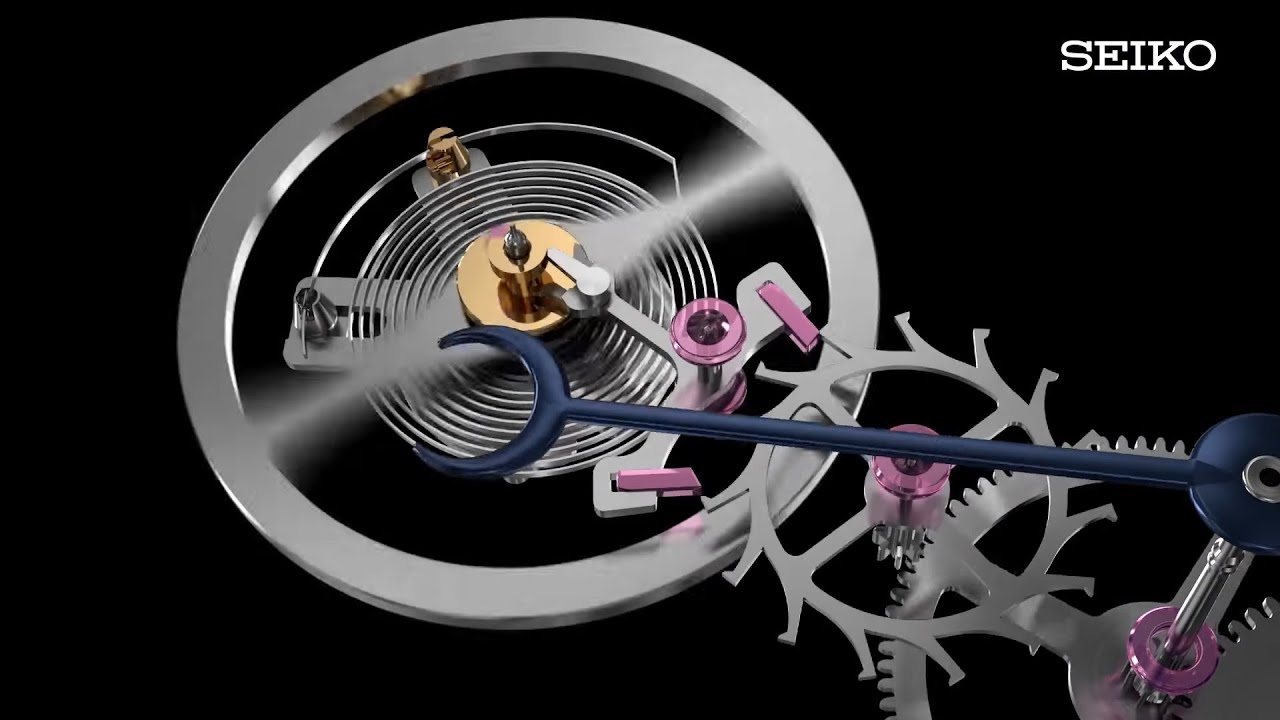

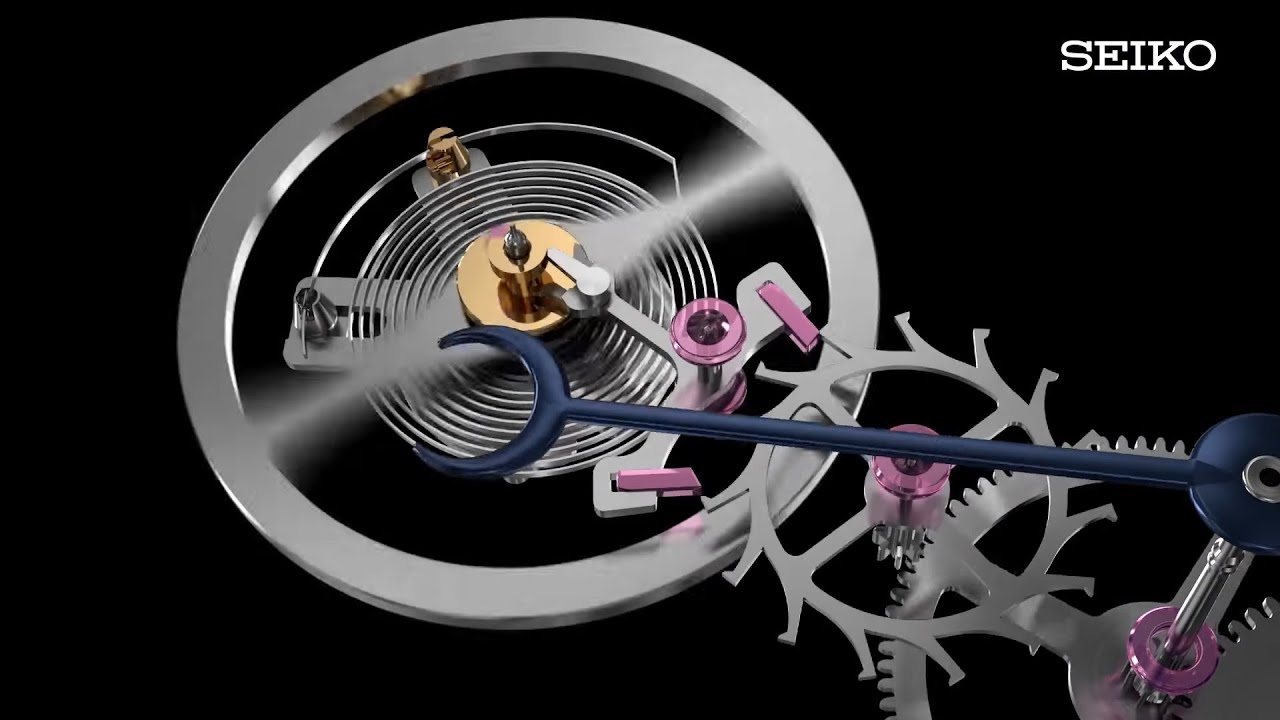

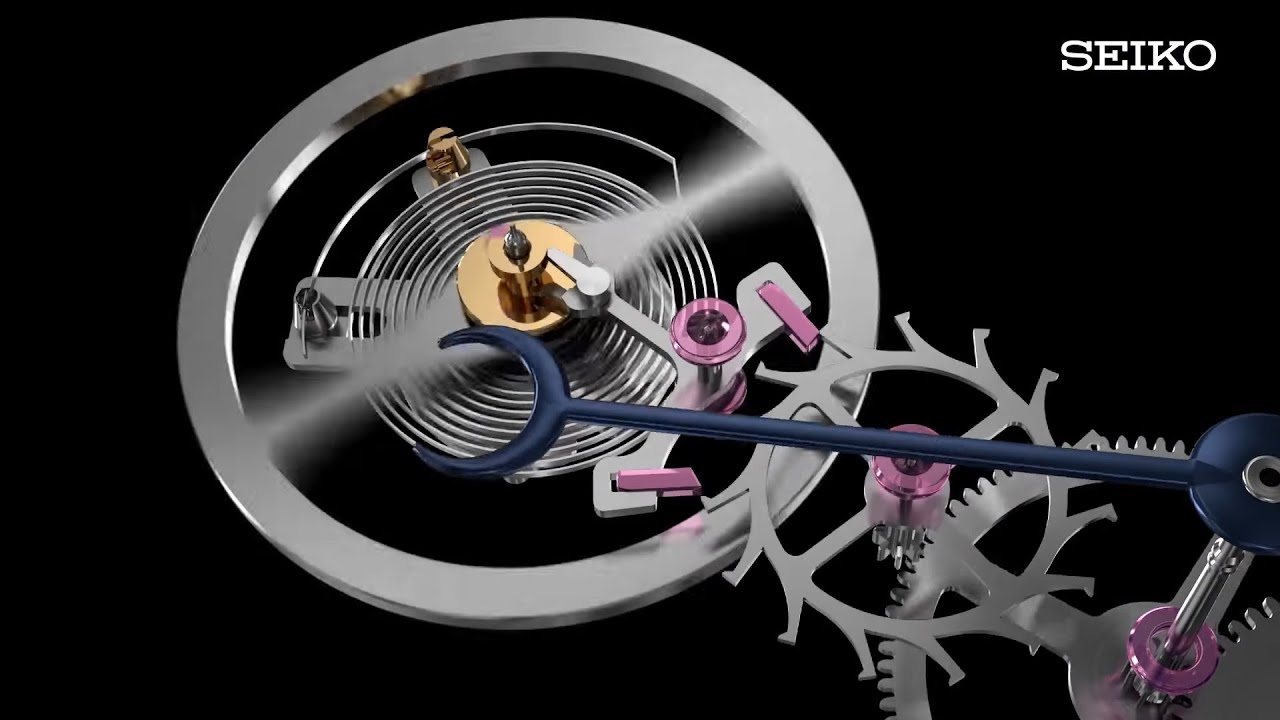

Having seen a bunch (maybe 300?) of these come across my desk I think I can add some value from a different perspective. I very rarely service these movements as it is cheaper and a better result for the customer to simply replace the movement and then regulate it. I consider them just about disposable. You can argue with me if you like, but present a good argument! Oiling by the SEIKO robots is crap. It's everywhere or nowhere. That said, even if it is crap, it will last for 5 years. A roached out A variant from 1997 is not better than 20+ years of refinement with the latest C version (they are up to like rev. 24 or something). The lower arbor jewel alone makes it worth the upgrade. My labour cost is twice the cost of the movement. So it's better to replace the movement every 5 years or so + the labour to fit. The customer ends up $50 or so better off every service time. I give a small trade in value on the old movements as I can use the parts. As I said in the other thread, the changes to the C variant are good and useful. The ETACHRON pin on the regulator is useful and brings the movement in line with the rest of the world. It's an attempt to address the shit performance of SEIKO movements. As you can't make a perfectly flat oscillating spring, you will always have some bend up and down on the spring when it's oscillating. The ETACHRON system allows you to adjust for that somewhat to help correct running issues. The old SEIKO system is difficult to tune, is solid, but horribly dated. It isn't difficult to use the ETACHRON system but you really need to buy the proper adjustment tool for it. There's a challenge for you guys! Make it flat as! youtu.be/yi39uk6_ZvE?t=802The only way to adjust for this on the old SEIKO system is to bend the pin slightly which is a shit solution. On the later chronometer grade movements (45, 52, 56, 61 etc) they have either a screw or "tadpole" to fine tune the regulator pins which is essential to achieving chronometer performance. As most watchmakers aren't skilled enough to actually use the system (there, I've said it and I don't care), they don't understand it and consider it pointless and/or a hassle. So they will say it's bullshit. The reason the Breguet style hairspring exists is to try and eliminate spring bend up and down when oscillating as much as possible. It does work and makes total sense if you sit there and watch how it works for a bit. Hence a "free sprung" balance. I really like the ROLEX micro stella regulating system. You get the benefit of having a free sprung balance with a relatively simple way to adjust it, and the adjustemnt doesn't drift. Of course again, most watchmakers don't understand it so say it's bullshit. Bear in mind we are talking about a sub $100 movement here. It's a marvel of modern design, in fact so good, it's not worth fixing. Having these high end features on such a cheap movement, really, you've won the lottery, but don't realise you have. It's simply from a lack of understanding about what this stuff actually is. There's my argument in the 7S26 debate! Adrian. There is the other issue, one which Spencer often mentions, which is a problem with the 7s26c, 4r, and 6r movements. Inconsistent and imprecise lubrication at point of manufacture. I cannot validate the veracity of this as a widespread and systemic issue but it has been an issue he has observed on multiple exemplars that cross his bench. He is quick to point out that properly lubricated and regulated the entire family is capable of very good numbers and accuracy. But he is a 7s26a fan. I have had all three, one 4r, and one NH35, and have not had any issues with any of them. But given the sheer numbers of these movements produced one would hope that the out of the box performance would tend toward consistency and within spec. |

|

Adrian-VTA

Global Moderator

Adelaide, South Australia

Posts: 5,327

|

Post by Adrian-VTA on Oct 29, 2019 21:10:05 GMT -8

There's no difference in the escape system (fork and wheel) between the A and C variant. Part numbers are the same. It's most likely one of the stones moved or a pivot was damaged. Adrian. There is the other issue, one which Spencer often mentions, which is a problem with the 7s26c, 4r, and 6r movements. Inconsistent and imprecise lubrication at point of manufacture. I cannot validate the veracity of this as a widespread and systemic issue but it has been an issue he has observed on multiple exemplars that cross his bench. He is quick to point out that properly lubricated and regulated the entire family is capable of very good numbers and accuracy. But he is a 7s26a fan. I have had all three, one 4r, and one NH35, and have not had any issues with any of them. But given the sheer numbers of these movements produced one would hope that the out of the box performance would tend toward consistency and within spec. Good to note Saul  Spencer also found issues with the escape system on the 'B' and perhaps the 'C' as well. In one example of a 'B' that he could not make behave, he replaced some 'A' parts into a 'B' and got the results expected. The movement then performed as it should have. I don't know if Seiko changed the escapement on the 'C' version but it stands to reason that they should have; knowing the short comings of the 'B'  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Oct 30, 2019 8:02:26 GMT -8

Having seen a bunch (maybe 300?) of these come across my desk I think I can add some value from a different perspective. I very rarely service these movements as it is cheaper and a better result for the customer to simply replace the movement and then regulate it. I consider them just about disposable. You can argue with me if you like, but present a good argument! Oiling by the SEIKO robots is crap. It's everywhere or nowhere. That said, even if it is crap, it will last for 5 years. A roached out A variant from 1997 is not better than 20+ years of refinement with the latest C version (they are up to like rev. 24 or something). The lower arbor jewel alone makes it worth the upgrade. My labour cost is twice the cost of the movement. So it's better to replace the movement every 5 years or so + the labour to fit. The customer ends up $50 or so better off every service time. I give a small trade in value on the old movements as I can use the parts. As I said in the other thread, the changes to the C variant are good and useful. The ETACHRON pin on the regulator is useful and brings the movement in line with the rest of the world. It's an attempt to address the shit performance of SEIKO movements. As you can't make a perfectly flat oscillating spring, you will always have some bend up and down on the spring when it's oscillating. The ETACHRON system allows you to adjust for that somewhat to help correct running issues. The old SEIKO system is difficult to tune, is solid, but horribly dated. It isn't difficult to use the ETACHRON system but you really need to buy the proper adjustment tool for it. There's a challenge for you guys! Make it flat as! youtu.be/yi39uk6_ZvE?t=802The only way to adjust for this on the old SEIKO system is to bend the pin slightly which is a shit solution. On the later chronometer grade movements (45, 52, 56, 61 etc) they have either a screw or "tadpole" to fine tune the regulator pins which is essential to achieving chronometer performance. As most watchmakers aren't skilled enough to actually use the system (there, I've said it and I don't care), they don't understand it and consider it pointless and/or a hassle. So they will say it's bullshit. The reason the Breguet style hairspring exists is to try and eliminate spring bend up and down when oscillating as much as possible. It does work and makes total sense if you sit there and watch how it works for a bit. Hence a "free sprung" balance. I really like the ROLEX micro stella regulating system. You get the benefit of having a free sprung balance with a relatively simple way to adjust it, and the adjustemnt doesn't drift. Of course again, most watchmakers don't understand it so say it's bullshit. Bear in mind we are talking about a sub $100 movement here. It's a marvel of modern design, in fact so good, it's not worth fixing. Having these high end features on such a cheap movement, really, you've won the lottery, but don't realise you have. It's simply from a lack of understanding about what this stuff actually is. There's my argument in the 7S26 debate! Adrian. There is the other issue, one which Spencer often mentions, which is a problem with the 7s26c, 4r, and 6r movements. Inconsistent and imprecise lubrication at point of manufacture. I cannot validate the veracity of this as a widespread and systemic issue but it has been an issue he has observed on multiple exemplars that cross his bench. He is quick to point out that properly lubricated and regulated the entire family is capable of very good numbers and accuracy. But he is a 7s26a fan. I have had all three, one 4r, and one NH35, and have not had any issues with any of them. But given the sheer numbers of these movements produced one would hope that the out of the box performance would tend toward consistency and within spec. I can't argue with anything you've said here. My point of view is from an enthusiast who prefers to do his own work so that servicing costs do not apply. I am not one of those who would ever equate the ETA 2824 with any Seiko less than, say, the 8l35 or some of the vintage 4xxx or 5xxx series. The 7s, and 4r series are basic entry level calibres with the 6r now approaching mid tier. For basic pedestrian watches, the value and performance of the 7s and 4r movements is tough to beat...unless you go with a Chinese movement. My position is that the 7s26(any version) is the perfect movement to learn on. It is inexpensive, easy to find and has an almost endless supply of parts. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Oct 30, 2019 8:29:02 GMT -8

There's no difference in the escape system (fork and wheel) between the A and C variant. Part numbers are the same. It's most likely one of the stones moved or a pivot was damaged. Adrian. Good to note Saul  Spencer also found issues with the escape system on the 'B' and perhaps the 'C' as well. In one example of a 'B' that he could not make behave, he replaced some 'A' parts into a 'B' and got the results expected. The movement then performed as it should have. I don't know if Seiko changed the escapement on the 'C' version but it stands to reason that they should have; knowing the short comings of the 'B'  I was talking about the balance assembly, not the escapement; which I believe Spencer thought might be the problem. Also, thanks for that very informative video. The fellow very nicely explained all the things I rather crudely point out. I'm not sure why he tried to differentiate between moving the regulator bar and adjusting the regulator pins. Moving the regulator does changed the effective spring length but so does adjusting the regulator pins. the difference is that regulator pins when adjusted, effectively reduce or increase the effective spring length in a micro fashion. If the pins are too far apart then the effective spring length will be greater on the expansion stroke vs the compression stroke. The etachron system simple makes it easy to reduce that difference so that there will be almost zero difference in compression or expansion mode. Moving the bar is simply the gross movement to adjust the stabilized spring length. When you see how easy it is to adjust the regulator pins with this system, you can get a pretty good idea of how difficult and what a PITA manually bending regulator pins must be. I'm willing to bet that Seiko never did any manual regulator work at the factory other than pushing the bar back and forth. This would go a long way to explaining the factory specs of +45/-25 spd(which would be an average over 6 positions). |

|

Adrian-VTA

Global Moderator

Adelaide, South Australia

Posts: 5,327

|

Post by Adrian-VTA on Oct 31, 2019 16:41:53 GMT -8

I'd never mess around with regulator pins on the older regulator. It's a recipe for trouble. It's why the non chronometer movements have shitty isochronism. There's no difference in the escape system (fork and wheel) between the A and C variant. Part numbers are the same. It's most likely one of the stones moved or a pivot was damaged. Adrian. I was talking about the balance assembly, not the escapement; which I believe Spencer thought might be the problem. Also, thanks for that very informative video. The fellow very nicely explained all the things I rather crudely point out. I'm not sure why he tried to differentiate between moving the regulator bar and adjusting the regulator pins. Moving the regulator does changed the effective spring length but so does adjusting the regulator pins. the difference is that regulator pins when adjusted, effectively reduce or increase the effective spring length in a micro fashion. If the pins are too far apart then the effective spring length will be greater on the expansion stroke vs the compression stroke. The etachron system simple makes it easy to reduce that difference so that there will be almost zero difference in compression or expansion mode. Moving the bar is simply the gross movement to adjust the stabilized spring length. When you see how easy it is to adjust the regulator pins with this system, you can get a pretty good idea of how difficult and what a PITA manually bending regulator pins must be. I'm willing to bet that Seiko never did any manual regulator work at the factory other than pushing the bar back and forth. This would go a long way to explaining the factory specs of +45/-25 spd(which would be an average over 6 positions). |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 7, 2019 12:20:49 GMT -8

Ok, it's time for an update with some fresh pics and measurements. First let's look at the Seiko parts comparison... Balance / Escapement Balance cock 0171 107(A) 0171 197(B) 0171 355(C) Etachron Balance cock screw 0012 420(A) <--(B) <--(C) Balance complete with stud 0310 020(A) 0310 197(B) <--(C) B, C Etachron new P/N 0310 183 NH25/26: 0311 050 Balance Diashock (upper and lower) cap jewel 0011 220(A) <--(B) <--(C) Balance Diashock (upper and lower) frame spring 0014 577(A) <--(B) <--(C) Balance Diashock (upper and lower) hole jewel with frame 0014 295(A) <--(B) <--(C) Pallet bridge 0161 300(A) <--(B) <--(C) Pallet bridge screw, Q.ty 2 0012 354(A) <--(B) <--(C) Pallet fork and staff 0301 009(A) <--(B) <--(C) Regulator N/A(A) 0341 020(B) <--(C) Etachron Stud arm 0345 007(A) 0345 197(B) <--(C) Etachron Stud screw 0012 123(A) N/A(B) N/A(C) All three balance cocks are different. The A and B for the obvious changes to the stud arm and the regulator arm. Since the B and C have the same Etachron system then the C must have a different shaped cock to fit the new rationalized main plate. Of note is that the 7s26 B and C have different part numbers for the Balance with stud than the B and C versions of the NH25/26. Wonder what that's all about? Some new pics with measurements...7s26A balance system  Here we can see the 7s26A fixed stud and it's retaining screw. The length of the stud from(left) to (right) is 0.98mm  This is the regulator with pin for the 7s26A. It measures 1.12mm from head of the pin to the tail of the holder. As you can see, the spring is held captive and cannot jump out of the regulator.  This pic shows the stud on the left and the regulator on the right. As Adrian has pointed out, making adjustments to either the stud or the regulator will end with tears. The only adjustment to be made at the stud is bending the spring; not a good idea. The only adjustment that might be made to the regulator pin would be to bend it inward toward the block but that would then leave a 'V' shaped slot for the spring to ride in; also not a good idea. So the best we can do is regulate the effective hairspring length and hope for the best. Now on to the 7s26B balance system...  side view  Along with the picture of the 7s26C farther up the page we can see here how different the A vs B/C versions are. Not only can the stud be adjusted to be closer or farther from the center oc the balance wheel but it can be turned to angle the hairspring as it exits on it's way to the regulator 'pin'. The height of the stud from top to bottom is 1.05mm. The regulator is 1.28mm. The balance regulator is now a slotted and tapered pin. This pin can also be moved closer to or farther away from the center of the balance wheel. Additionally, it can be turned, thereby reducing or increasing the slot opening relative to the spring. It should only be turned in one direction for the best isochronism ;turning it the other way will upset isochronism and make it really difficult to get a clean line on the Timegrapher. Since the B and C balance plus stud are the same part. The regulator slot is open so there is little to keep it from being dislodged from a bump. Ideally, there should be no more or no fewer reports of looped hairsprings(see pic of B movement above) from the B and C versions. So Seiko did nothing to eliminate the jumping hairspring and subsequent looping around the stud  That is pretty much all I have to offer. Hopefully this takes care of some of the 'fake news' I reported earlier  Which version do I like best now? Well, I guess it would have to be the C version since it now shares so many parts with the 4r, 6r and 8r series. New parts will be available for many more years than for the older, dare I say, ancient A version. Finally a big thank you to Adrian who sent me some balance assemblies to photograph and get a good close up look without having to destroy a working watch  |

|

HiBeat

Global Moderator

SEIKO Iko Iko GDTRWS

Posts: 8,855

|

Post by HiBeat on Dec 7, 2019 14:53:35 GMT -8

I am thinking maybe this is worthy of being a sticky in the tinkering area.

Thanks Peter !!!

|

|

7s26b

Timekeeper

Tmesis

Posts: 233

|

Post by 7s26b on Dec 9, 2019 5:10:48 GMT -8

Thanks for clearing that up Pete, it's been bugging me for quite a while now.

Good to see some hard facts!

I was thinking how on earth could it be different if the adjustable stud is a common part number to 4R35a and 4R15/16?

I was also wondering if the balance cock was modified at the time to accept the modified yoke and yoke springs? -hence the part number change?

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 9, 2019 8:33:28 GMT -8

Thanks for clearing that up Pete, it's been bugging me for quite a while now. Good to see some hard facts! I was thinking how on earth could it be different if the adjustable stud is a common part number to 4R35a and 4R15/16? I was also wondering if the balance cock was modified at the time to accept the modified yoke and yoke springs? -hence the part number change? The cocks for A and B are definitely different. The cutouts for the yoke and yoke springs look quite a bit different, particularly from the side. The stud bar on the A is much thicker than the forked holder on the B and C. The stud holder on the A has to be thick enough to hold the retaining screw. This ultimately made the cutouts on the A stud bar deeper and a slightly different shape. The C cock was changed to match the altered main plates of the various series. For example, a C balance assembly will not screw directly on to a A or B plate. One day if I get my hands on a C again, I may explore this further with more pics. For the C version, all of these parts were rationalized through the 7s, 4r and 6r series. As we've seen some smaller parts are shared but assembly level stuff has different numbers. |

|

7s26b

Timekeeper

Tmesis

Posts: 233

|

Post by 7s26b on Dec 9, 2019 8:53:56 GMT -8

Hi, I should have been more specific ref the balance cock change, I was referring to the B to C change (with new design springs underneath) , I don't know how the springs are different, shape, hole size or thickness?

It's always good to get more information!!

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 9, 2019 10:00:11 GMT -8

Hi, I should have been more specific ref the balance cock change, I was referring to the B to C change (with new design springs underneath) , I don't know how the springs are different, shape, hole size or thickness? It's always good to get more information!! Well, with examples of each in hand it would be easy to differentiate them but I don't have those samples  |

|

HiBeat

Global Moderator

SEIKO Iko Iko GDTRWS

Posts: 8,855

|

Post by HiBeat on Dec 9, 2019 15:52:25 GMT -8

Wearing this one today and flipped it over, it's a 7S26B.   |

|

|

|

Post by saul on Dec 9, 2019 17:33:47 GMT -8

I feel like this all belongs in the Blue Room.  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 9, 2019 21:40:33 GMT -8

I am thinking maybe this is worthy of being a sticky in the tinkering area. Thanks Peter !!! Agreed! Also, a 6R15 A/B/C/D sticky would be helpful as well. And then somehow link both of them to the Watchuseek Seiko forum so we can stop the uninformed masses from starting new "Why the 7s26A is superior" and "Is the 6R15D REALLY better than the 6R15C?" threads every two weeks. |

|